-

ARPAK

Where the medical industry meets packaging industry.

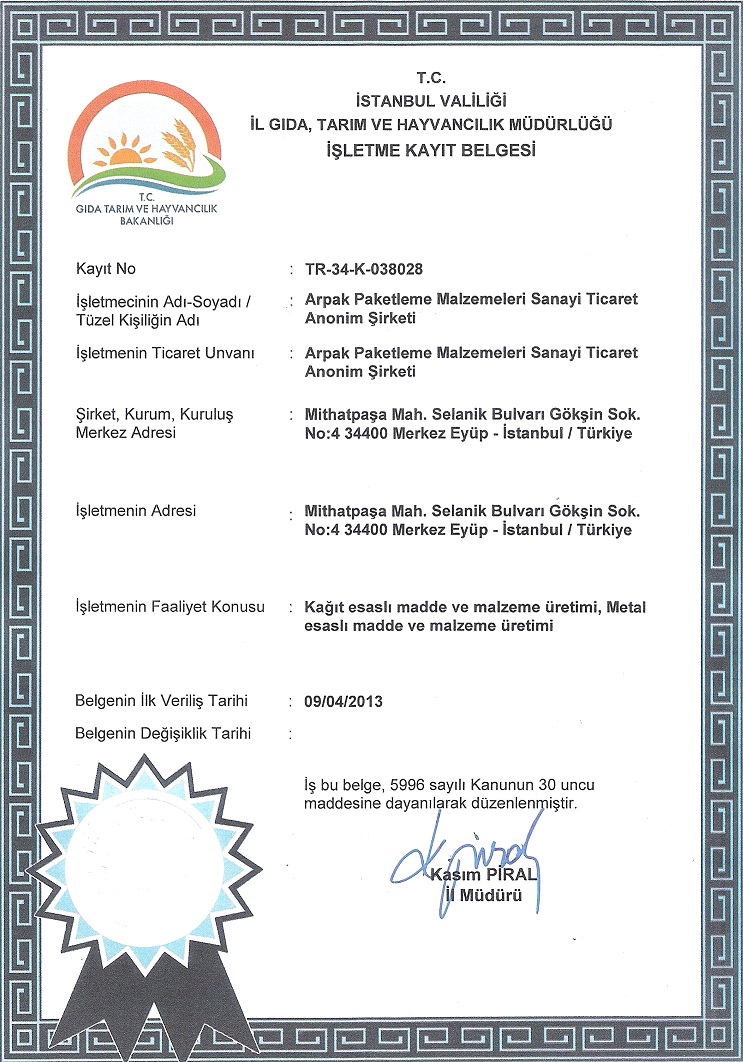

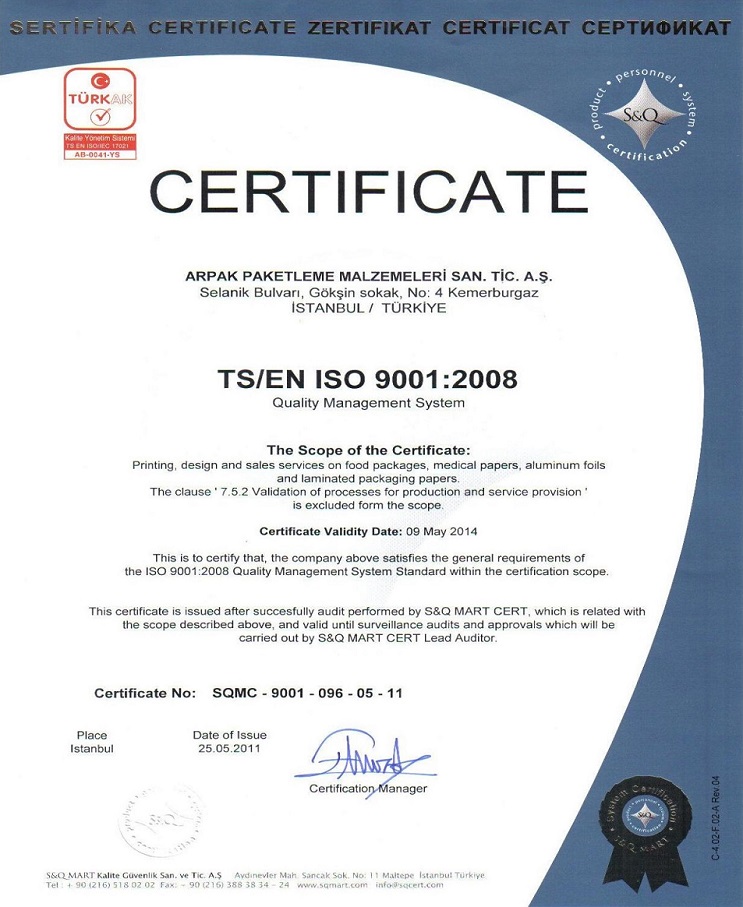

In 1987 the company started production under the name PÜRKİM Ltd. and in 1994 took the name Arpak Paketleme Malzemeleri San.ve Tic.A.Ş., specialising in printing and slicing of two important packaging materials for the medical industry.

The foil used for packaging of disposal syringes, catheters, surgery disposables and similar products are produced from Arjo Wiggins papers. Printing is done according to design stated by the customer. The paper has the property to be sterilised with EO gas, both sides of the paper can be printed and both ability to bond PS type packaging foils. Under sterilisation with EO gas, the pores of the paper become larger, allowing transfer of the gas in packed material.

The product, blister type aluminium foil, is used for packaging of pills of different types. One side of the aluminium foil is treated with heat seal lacquer, the other side contains the printing of the name of product. The printed side is coated with suitable primer and top-coat lacquer. The blister foil can be heat sealed at 250 °C without any damage to the printing. -

ARPAK Paketleme Malzemeleri San. ve Tic. A.Ş.

ARPAK A.Ş. is a converter of medical paper, PE coated medical paper suitable for ethylene oxide and gamma radiation sterilisation, 7-15 micron aluminium and 20 micron aluminium foil (blister) foils used in medical industry for packaging purposes. The company’s major involvement is in printing of aluminium foil and medical paper, and slicing of the reels according to customer requirement. Besides, the company has the capability to realise dry lamination of OPP; PE, PP and similar packaging foils as well as wet lamination of aluminium and paper products.

ARPAK, member of GÖKŞİN Group of companies, started in year 1984 as converter of foils for food packaging, and in 1994 has converted its interest in to medical industry and today ARPAK became major supplier in local and foreign markets.

Main usage of the our packaging foils are;

- 1. Medical paper for disposable articles such as syringes, catheters etc.

- 2. Heat sealable PE coated medical paper and medical paper for sterile gauze, bandage, elastic bandage, capsicum plaster, pads and dressing packaging.

- 3. Aluminium foil (as blister) for drug packaging.

- 4. Aluminium foil + paper laminated packaging foils for fast-food sector.

- 5. Ready packaging (envelope) for sterile gauze and similar disposable articles.

- 6. Medical paper suitable for Ethylene Oxide and Gamma ray sterilisation for packaging of sterilisation rolls.

In order to maximise customer satisfaction, increase production process speed and achieve higher efficiency levels, besides its high quality, ARPAK supports its customers in preparation stage; mainly in the making of the customer required design for their packaging, choice of foil, making of the cliché and similar customer services. The company has close contact to its customer in solving their problems such as selection of the suitable foil for their packaging machine, heat and pressure sensitive paint selections, printing special codes on packaging for storage control, printing of barcode’s and pharmacode’s for securing product control; all with the support of our experienced staff.

-

Products

1. Medical Paper

2. Aluminium Foil

Medical Paper (Direct seal)

Used for packaging of disposable syringes, medical equipments and similar products. It is suitable for ethylene oxide gas and gamma radiation sterilization, it adheres with heat on transparent films made of PA/PE and PVC. It has excellent peeling properties with no dust formation, the printing is done on glossy side resulting in high quality. The paper is easy to peel, has high tear resistance and the medical item remains sterile through out its shelf life. It is widely approved and accepted in European and Asian countries. Please contact us for detailed information.

PE Medical Paper (PE coated Paper)

The PE coated medical paper is mostly used as 50 g/m2 paper with 20 micron PE coating, other paper specifications and PE film thicknesses are also available, they are produced according to customer request. The high bacteria barrier property of the medical paper results in great use in packaging of surgical gloves, surgical pads, sterile gauze, bandage, elastic bandage, capsicum plaster, pads, dressing and medical equipment. It is suitable for gamma radiation sterilization. It has high adhesion property and does not produce paper filament during peeling.

Medical Sulphide Paper

Medical sulphide paper, mostly preferred as 50-70 g/m2, is commonly used in packaging of syringe, gauze, pad and medical equipment packaging.

Blister Foil (20 micron, Heat Seal Lacquer coated)

The mat side of the 20 micron aluminium foil is printed according to the customer request and the glossy side is coated with Heat Seal Lacquer, it is used for packaging of drugs in tablet or similar form. It is also known as Blister Foil. The lacquer is applied around 5-7 g/m2 on inside of the foil and this enables the foil to adhere on PVC, PP, PVDC and similar foils with excellent sealing property. Sealing is done with a pressure plate applying a pressure of 40kg/sec. resulting in peeling strength of 9 N/15 mm. The protective lacquer on printing prevents the printing from peeling off and increases its heat resistance above 200 C. The colour of the print and size of the reels are done according to customer specifications, the low cost of cliché in Flexographic printing system enables quick change in design of printing.

Aluminium Foil (7-15 micron, without lacquer)

Aluminium foil between 7-15 micron thickness is printed according to the design and colour stated by the customer. Majority of this kind of foil is used for chocolate packaging. The foil is supplied in ready to use form either in smooth or embossed finish resulting in excellent appearance. The colour of the print and size of the reels are done according to customer specifications, the low cost of cliché in Flexographic printing system enables quick change in design of printing.

Aluminium Foil (10 micron aluminium, laminated with paper)

10 micron aluminium foil laminated to sulphide paper result in perfect packaging for the fast food industry. The printing is realised on aluminium foil, use of specially designed lamination cliché results in increase of aesthetic appearance on both sides of the product. The laminated foil is preferred and widely used by high end fast food producers due to the capability of the packaging to keep the food warm for longer period of time.

-

Contact Informations

ARPAK PAKETLEME MALZEMELERİ SAN.TİC. A.Ş.

Selanik Bulvarı Gökşin Sokak No:4

Vergi Dairesi:

Vergi No:

Telefon:

Fax:

Web:Gaziosmanpaşa

0800030618

+90 212 360 00 49

+90 212 360 27 98

www.arpak.comYetkili Kişi:

Telefon:

Email:Ali Rıza Şahin

+90 532 250 38 03

alirizasahin@arpak.comContact Form

ARPAK Paketleme Malzemeleri San. ve Tic. A.Ş.